Ductwork

Ductwork Residential

Ductwork is a crucial component of any HVAC

What Is Ductwork and How Does It Work?

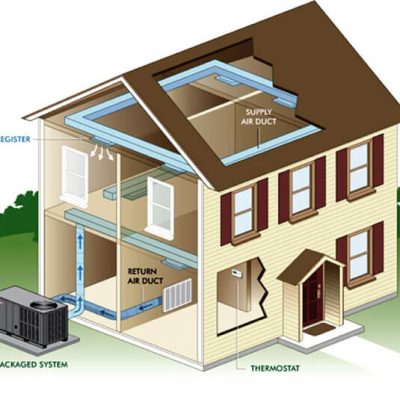

Have you ever wondered how conditioned air reaches every corner of your home to keep you and your family safe and comfortable? The secret lies within a network of tubes called ductwork.

The Main Components of an Air Duct System

Without getting too technical, ductwork is best described as a network of metal or flexible pipes that transport conditioned air from your HVAC system to air vents, which then distribute the air into your home’s living areas. Ducts typically snake through attics, crawlspaces, or basements – delivering cool air in summer and warm air in winter.

As we have seen, HVAC systems really do depend on ductwork. Let’s now look at an overview of the main ductwork elements:

Duct Trunks and Pipes

- Duct trunks are the main method of carrying conditioned air from the AC to other parts of the building. They are often constructed from sheet metal.

- Duct pipes extend from the trunks and then route air to specific rooms and are made from steel or aluminium depending on where they’re installed.

- Additional parts such as stack boots and stack heads help channel air vertically between floors, improving air distribution between levels.

Transitions

- Transitions connect duct components and allow for smooth directional changes and airflow continuity between trunks and pipes.

- The take-off transfers air from the main trunk to the branch pipe

- Other types include turning vanes (which help air flow smoothly around corners) and cleats (used to join duct sections securely).

- Well-designed transitions reduce turbulence and resistance, which can otherwise negatively impact airflow and increase energy usage.

Plenum Boxes

- Supply plenum: These distribute conditioned air from the unit into the duct system.

- Return plenum: Collects air from rooms using return ducts and then channels it back to the HVAC unit.

- Efficient plenum design is vital as it helps maintain consistent temperature and pressure throughout the duct network.

Supply and Return Ducts

- Supply ducts deliver heated or cooled air into living spaces.

- Return ducts pull indoor air back to the HVAC unit for filtering and to adjust the temperature.

- A well-balanced ratio of supply to return ducts means you get even airflow and good indoor air quality.

Vents and Registers

- Registers are the visible covers for supply vents and they are often equipped with dampers to control airflow into a room.

- Return vents usually do not have adjustable features and are designed to draw in air for recirculation.

- Correct placement and sizing of vents and registers help optimise comfort and system performance.

Dampers

- Dampers are devices which are installed within ducts or at registers to control airflow to specific zones.

- Manual or automatic dampers can be used in zoned HVAC systems to regulate temperature by redirecting airflow.

- They enhance energy efficiency and occupant comfort by preventing over-conditioning of unused areas.

Air Handler Unit (AHU)

The AHU is responsible for moving, conditioning, and distributing air throughout the ductwork system. It contains critical HVAC components:- Blower fan: Circulates air through the duct system.

- Dampers: Control airflow volume.

- Heating/cooling coils: Adjust air temperature.

- Filters: Remove dust and allergens from the airstream.

Flues

- Flues are exhaust ducts used in HVAC systems with combustion-based heating.

- They vent combustion gases safely out of the home.

- Proper flue installation is critical for indoor air safety and compliance with building codes.

Ductwork plays a central role in the HVAC process. Let’s now look at how it functions in more detail:

Air collection: The process begins when air is drawn from different rooms through return vents. The vents are in turn connected to return ducts which carry the indoor air back to the HVAC unit.

Conditioning: Once the air reaches the air handler unit it is filtered to remove dust and allergens, then either heated or cooled depending on the thermostat setting.

Redistribution: The conditioned air is then pushed by a blower fan into the supply plenum, which directs it into the supply ducts. These ducts branch out to different rooms, delivering the treated air through supply vents or registers.

Let’s now look at the different types of ductwork:

- Flexible Ductwork: Flexible ducts are made from a metal wire coil covered in plastic and wrapped in thermal insulation. These ducts are compact and ideal for tight spaces where rigid ducts won’t fit.

- Rigid Ductwork: Rigid duct systems are long-lasting and offer better airflow and are less prone to damage or sagging. They include:

- Sheet Metal Ducts: Made from galvanised steel or aluminium, these non-porous ducts resist mould growth and are easy to clean, making them a reliable choice for both homes and commercial spaces.

- Fiberglass-Lined Ducts: Lined with sound-dampening insulation, these are common in offices but can deteriorate over time, releasing particles that may affect air quality and health.

- Fiberboard Ducts: Made from compressed fibreglass with foil facing for moisture protection. While well-insulated, they are not ideal for ventilation due to their porous nature, which can promote mould growth.

Ductwork Commercial

Ductwork is a crucial component of any HVAC

Ductwork is a crucial component of any HVAC (Heating, Ventilation, and Air Conditioning) system and in this article we will look at what exactly ductwork is as well as how it works in detail. We will examine the various different types of ductwork that are available, as well as tips to keep it running efficiently. So whether you’re putting together a new HVAC system or maintaining your current one, this guide will help you understand how it can impact both comfort and performance.

As we have seen, HVAC systems really do depend on ductwork. Let’s now look at an overview of the main ductwork elements:

Duct Trunks and Pipes

- Duct trunks are the main method of carrying conditioned air from the AC to other parts of the building. They are often constructed from sheet metal.

- Duct pipes extend from the trunks and then route air to specific rooms and are made from steel or aluminium depending on where they’re installed.

- Additional parts such as stack boots and stack heads help channel air vertically between floors, improving air distribution between levels.

Transitions

- Transitions connect duct components and allow for smooth directional changes and airflow continuity between trunks and pipes.

- The take-off transfers air from the main trunk to the branch pipe

- Other types include turning vanes (which help air flow smoothly around corners) and cleats (used to join duct sections securely).

- Well-designed transitions reduce turbulence and resistance, which can otherwise negatively impact airflow and increase energy usage.

Plenum Boxes

- Supply plenum: These distribute conditioned air from the unit into the duct system.

- Return plenum: Collects air from rooms using return ducts and then channels it back to the HVAC unit.

- Efficient plenum design is vital as it helps maintain consistent temperature and pressure throughout the duct network.

Supply and Return Ducts

- Supply ducts deliver heated or cooled air into living spaces.

- Return ducts pull indoor air back to the HVAC unit for filtering and to adjust the temperature.

- A well-balanced ratio of supply to return ducts means you get even airflow and good indoor air quality.

Vents and Registers

- Registers are the visible covers for supply vents and they are often equipped with dampers to control airflow into a room.

- Return vents usually do not have adjustable features and are designed to draw in air for recirculation.

- Correct placement and sizing of vents and registers help optimise comfort and system performance.

Dampers

- Dampers are devices which are installed within ducts or at registers to control airflow to specific zones.

- Manual or automatic dampers can be used in zoned HVAC systems to regulate temperature by redirecting airflow.

- They enhance energy efficiency and occupant comfort by preventing over-conditioning of unused areas.

Air Handler Unit (AHU)

The AHU is responsible for moving, conditioning, and distributing air throughout the ductwork system. It contains critical HVAC components:- Blower fan: Circulates air through the duct system.

- Dampers: Control airflow volume.

- Heating/cooling coils: Adjust air temperature.

- Filters: Remove dust and allergens from the airstream.

Flues

- Flues are exhaust ducts used in HVAC systems with combustion-based heating.

- They vent combustion gases safely out of the home.

- Proper flue installation is critical for indoor air safety and compliance with building codes.

Ductwork plays a central role in the HVAC process. Let’s now look at how it functions in more detail:

Air collection: The process begins when air is drawn from different rooms through return vents. The vents are in turn connected to return ducts which carry the indoor air back to the HVAC unit.

Conditioning: Once the air reaches the air handler unit it is filtered to remove dust and allergens, then either heated or cooled depending on the thermostat setting.

Redistribution: The conditioned air is then pushed by a blower fan into the supply plenum, which directs it into the supply ducts. These ducts branch out to different rooms, delivering the treated air through supply vents or registers.

Let’s now look at the different types of ductwork:

- Flexible Ductwork: Flexible ducts are made from a metal wire coil covered in plastic and wrapped in thermal insulation. These ducts are compact and ideal for tight spaces where rigid ducts won’t fit.

- Rigid Ductwork: Rigid duct systems are long-lasting and offer better airflow and are less prone to damage or sagging. They include:

- Sheet Metal Ducts: Made from galvanised steel or aluminium, these non-porous ducts resist mould growth and are easy to clean, making them a reliable choice for both homes and commercial spaces.

- Fiberglass-Lined Ducts: Lined with sound-dampening insulation, these are common in offices but can deteriorate over time, releasing particles that may affect air quality and health.

- Fiberboard Ducts: Made from compressed fibreglass with foil facing for moisture protection. While well-insulated, they are not ideal for ventilation due to their porous nature, which can promote mould growth.